Food Manufacturing: Expanding, Relocating, and Cutting Costs

The food and beverage manufacturing sector is currently navigating a period of intense transformation. Faced with rising raw material costs and shifting consumer habits, many manufacturers are finding that their current facilities simply cannot support their future goals. For many, the path forward involves strategic expansion, relocation, or consolidation through Mergers and Acquisitions (M&A). However, these are not just financial decisions; they are construction challenges. A poorly planned facility can bleed money for decades, while an optimized plant can become your competitive advantage.

This detailed guide outlines the critical insight steps you must take when planning your next move.

Table of Contents

Managing M&A Consolidation

Building New vs. Buying Existing

Designing for Cost Reduction

Utilities and Infrastructure

Hygiene and Compliance

Future-Proofing for Automation

1. Managing M&A Consolidation

In today's market, growth often looks like acquisition. But once the deal is signed, the real work begins: merging two physical operations into one. The goal is to eliminate redundancy, but the risk is operational chaos.

The Key Insight: The cost of downtime often exceeds the cost of construction.

Detailed Action Steps:

Audit Capacity First: Before moving equipment from Plant A to Plant B, perform a detailed utility audit. Does Plant B have the transformer capacity to run both lines simultaneously?

Phased Integration: Never move everything at once. Create a construction schedule that allows for "leapfrog" production—keeping one line running while the other is being installed and commissioned.

Cultural & Physical Safety: Merging companies means merging safety cultures. Ensure the physical facility meets the highest standard of the two companies, not the lowest.

2. Building New vs. Buying Existing

This is the "Greenfield" (new build) versus "Brownfield" (renovation) debate. While buying an existing warehouse seems cheaper upfront, food manufacturers must be wary of hidden costs.

The Key Insight: An existing warehouse is rarely "food-ready."

Detailed Action Steps:

Assess Drainage: Existing slabs rarely have adequate trench drains. Cutting concrete to install drainage is expensive and dusty. If the existing floor is weak, a new build might actually be cheaper.

Check Clear Heights: Food processing often requires vertical gravity-fed systems or high-pile cold storage. If an existing building’s roof is too low, you lose cubic volume efficiency.

Contamination Risks: Investigate the building's history. Was it used for chemicals or non-food manufacturing? Residual contaminants can prevent food safety certification.

3. Designing for Cost Reduction

Construction isn't just a cost; it is a tool to lower your Cost of Goods Sold (COGS). A smart layout reduces labor and energy bills every single day.

Detailed Action Steps:

Linear Flow: Design the facility so raw ingredients enter one side and finished goods leave the other. Every time a forklift has to turn around or cross paths, you lose money and increase safety risks.

Thermal Efficiency: In cold storage, the building envelope is critical. Use high-performance Insulated Metal Panels (IMPs) and fast-acting doors to stop money from escaping through the roof.

LED & Sensors: Install motion-sensor LED lighting in low-traffic areas (like freezers) to cut electrical load significantly.

4. Utilities and Infrastructure

A food plant is a heavy industrial machine. If the utilities aren't there, the plant doesn't run. This is the most common reason we see relocation projects stall.

The Key Insight: Municipal limits can kill a project before it starts.

Detailed Action Steps:

Wastewater Testing: Check the local municipality's BOD (Biochemical Oxygen Demand) and TSS (Total Suspended Solids) limits. If your effluent is too "dirty," you will need to budget $500k+ for an on-site treatment plant.

Water Pressure: Do you have enough volume for sanitation washdowns? You may need on-site storage tanks and booster pumps.

Power Availability: Lead times for new electrical substations can be 18-24 months. Confirm power availability immediately.

5. Hygiene and Compliance

Whether you are aiming for CFIA, FDA, SQF, or BRC certification, your building must do the heavy lifting for sanitation.

Detailed Action Steps:

Hygiene Zoning: Physically separate "Low Risk" (Raw ingredients/Packaging) from "High Care" (Cooked/Exposed product). Use color-coded flooring and separate air handling units to prevent cross-contamination.

The "Cleanability" Test: Avoid horizontal ledges. Use coved bases where walls meet floors. If water can pool there, bacteria will grow there.

Positive Air Pressure: Design HVAC systems to push air out of the cleanest rooms, ensuring dust and pathogens cannot fly in when a door opens.

6. Future-Proofing for Automation

You may not be using robotics today, but you will likely need them in 5 years. Expanding or relocating is the time to prepare the "bones" of the building.

Detailed Action Steps:

Super-Flat Floors: Automated Guided Vehicles (AGVs) require incredibly flat concrete floors to operate safely.

Structural Reinforcement: Ensure the roof structure can handle heavy suspended loads (like conveyors) and the floor can handle the point loads of high-density racking.

7. Case Study: TWI Foods Inc. Expansion

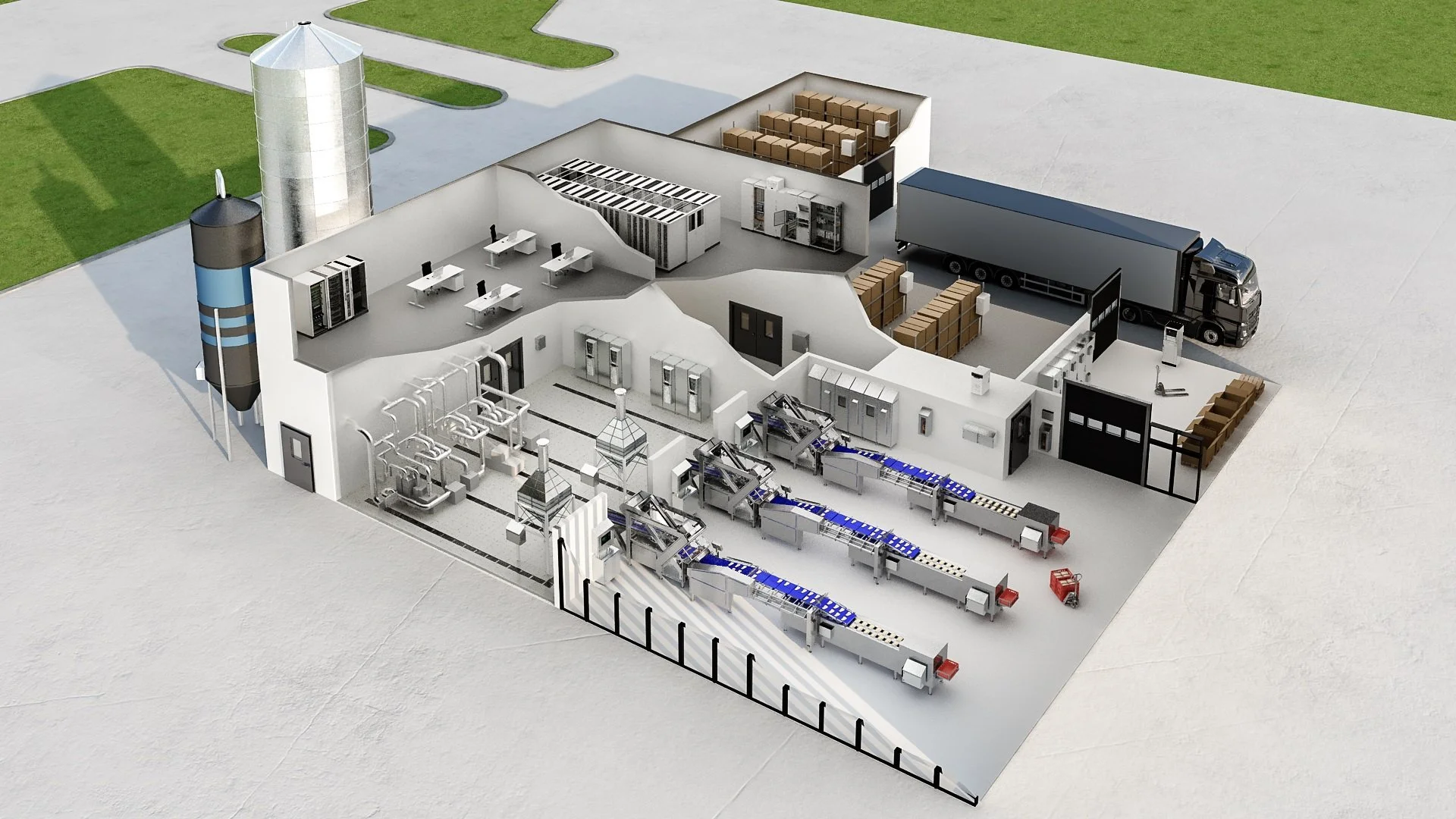

At HKC Construction, we don’t just advise on these principles we execute them in the real world. A prime example is our recent project for TWI Foods Inc. in Etobicoke, Ontario.

The Challenge

TWI Foods required a massive expansion to support their growing production needs. The project involved a complex logistical challenge: physically connecting two existing production buildings into a single, unified facility.

The Solution

HKC Construction managed the build of a 65,000 sq. ft. warehouse and shipping addition. This wasn't just a simple shell; it required high-level integration to ensure the facility functioned as one cohesive unit.

Key elements of the construction included:

Silo Installation: We managed the complex foundation and structural work required to install large exterior ingredient silos, feeding directly into the production lines.

System Integration: Merging the mechanical, electrical, and fire safety systems of the new addition with the existing buildings to ensure code compliance and safety.

Workflow Optimization: The connection of the buildings allowed for a seamless flow from production to the new shipping warehouse, reducing handling time.

By successfully bridging these two facilities, TWI Foods gained the capacity they needed without the downtime of a complete relocation.

Conclusion

Expanding or relocating is not just about finding more space; it is about building a competitive advantage. Every construction decision from the drainage layout to the insulation thickness impacts your margins and your food safety risks.

At HKC Construction, we understand the unique complexity of the food and beverage industry. Whether you are installing silos, merging plants, or breaking ground on a new facility, we build the engines that drive your production.

Build or Expand Your Food Plant

From CFIA/FDA compliant hygienic environments and cold storage to industrial utility upgrades and silo installations, we specialize in high-performance food manufacturing facilities.

.jpg)

.jpg?updatedAt=1765809859714)

.jpg?updatedAt=1765809858270)