18 Innovative Construction Materials That Surprise: Top New Trends Revolutionizing the Industry

The construction industry is undergoing a radical transformation driven by groundbreaking materials that challenge everything we thought we knew about building. As sustainability concerns intensify and climate change demands action, innovative construction materials are emerging from laboratories and forward-thinking manufacturers worldwide. These aren't just incremental improvements, they're revolutionary solutions that promise to reshape how we build, how long our structures last, and how much environmental damage construction causes.

At HKC Construction, we're committed to staying at the forefront of industry innovation. This comprehensive guide explores 18 cutting-edge materials that are revolutionizing the construction landscape in 2025 and beyond.

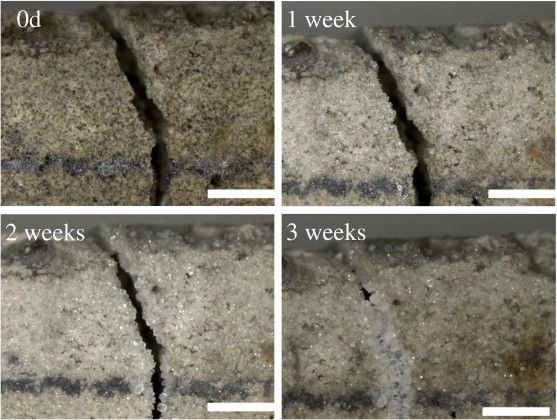

1. Self-Healing Concrete: Structures That Repair Themselves

What it is: Concrete embedded with bacteria or microcapsules that automatically seal cracks when exposed to water and air.

Why it matters: Self-healing concrete represents one of the most significant advances in concrete technology. Traditional concrete develops cracks over time, leading to costly repairs and reduced structural integrity. Self-healing variants extend the lifespan of concrete structures by decades, potentially lasting up to 200 years, while dramatically reducing maintenance costs.

Real-world impact: This technology is particularly valuable for foundations, driveways, and infrastructure projects where access for repairs is difficult or expensive. Early field tests demonstrate that maintenance costs can be cut significantly, meaning fewer warranty callbacks and stronger buildings over a 20-year period.

Performance metrics: Reduces maintenance needs by up to 80% compared to traditional concrete and extends material lifespan substantially.

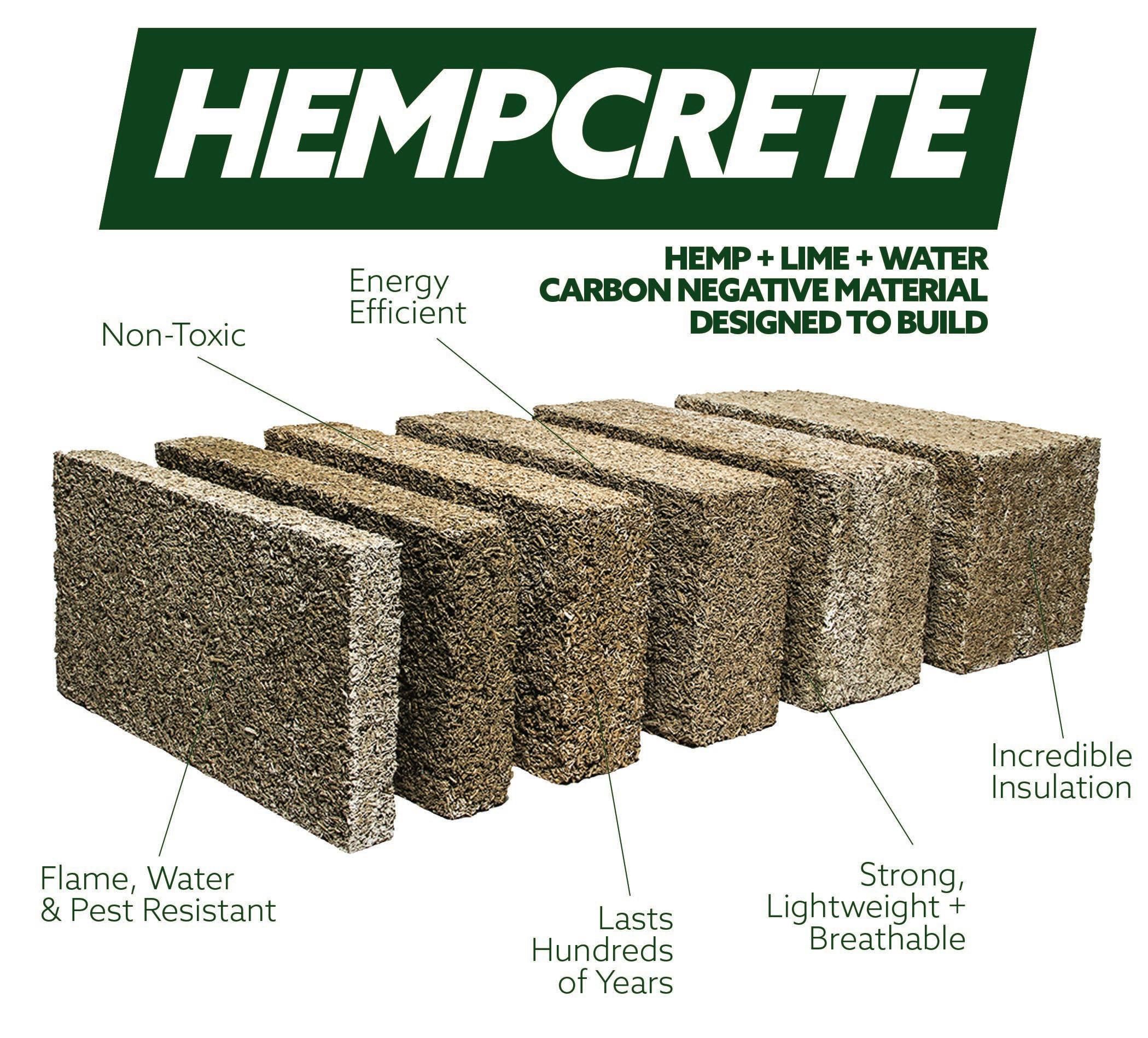

2. Hempcrete: Carbon-Negative Building Blocks

What it is: A biocomposite material made from hemp shiv (woody core), lime, and water that actively sequesters carbon during production and curing.

Why it matters: Hempcrete is gaining widespread recognition as one of the most environmentally responsible building materials available. Rather than emitting carbon dioxide like traditional concrete, hempcrete actually absorbs CO₂ during both growth and curing, making it carbon-negative.

Applications: Used primarily as non-load-bearing wall material with exceptional insulating properties. Its breathable nature makes it ideal for residential and low-rise commercial construction in regions following building codes permitting its use.

Sustainability advantage: Sequesters significant amounts of CO₂ while providing excellent thermal insulation, reducing both heating and cooling demands.

3. Mycelium-Based Composites: The Fungal Revolution

What it is: Building materials grown from mycelium (the root structure of mushrooms) that are fire-resistant, completely biodegradable, and created with minimal energy.

Why it matters: Mycelium represents a paradigm shift in material sourcing. Instead of manufacturing materials, we can literally grow them. These composites are fully compostable at end-of-life and require significantly less energy to produce than traditional alternatives.

Current applications: Interior wall paneling, acoustic tiles, and emerging structural elements. The material's fire-resistant properties make it particularly valuable for buildings with strict fire codes.

Sustainability profile: Completely biodegradable, minimal production energy, and can close the loop on waste streams when incorporated into buildings.

4. Graphene-Enhanced Concrete: Superhuman Strength

What it is: Standard concrete reinforced with graphene oxide, a single-layer carbon material that dramatically improves concrete properties.

Why it matters: Graphene-enhanced concrete is approximately 2.5 times stronger than standard concrete and allows four times less water penetration. This powerful combination of properties enables builders to use substantially less concrete while achieving equivalent or superior structural performance.

Performance breakthroughs:

30% increase in compressive strength after just 7 days

55% increase in compressive strength after 56 days

50% reduction in cement content required

Four times less water permeability

Potential 30% reduction in CO₂ emissions

Smart capabilities: Graphene's electrical conductivity allows integration of sensors throughout concrete surfaces for real-time monitoring of stress, deformation, temperature, and humidity.

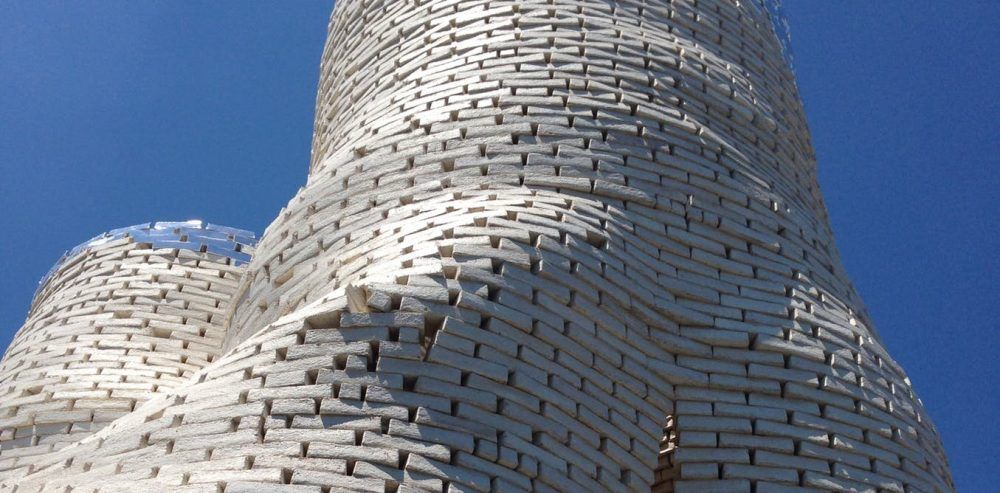

5. Bio-Blocks: Algae-Based Concrete Alternative

What it is: Building blocks created using naturally occurring microscopic algae that sequesters carbon through photosynthesis and biocementation.

Why it matters: Bio-Blocks represent zero-carbon construction materials. The micro-algae combines with water, sunlight, and CO₂ to create a material similar to calcium carbonate found in coral reefs. The resulting blocks have similar or improved physical and thermal performance compared to Portland cement concrete.

Global impact potential: If deployed at scale, Bio-Blocks could reduce global CO₂ emissions by up to 8%, a truly transformative impact.

Real-world deployment: SOM's Bio-Block Spiral installation at the Chicago Architecture Biennial demonstrates this technology's viability, reducing carbon emissions by one metric ton just by replacing traditional concrete blocks.

6. Cross-Laminated Timber (CLT): Engineered Wood's Moment

.jpg)

What it is: Engineered wood product made from sustainably managed forests, composed of cross-stacked layers of wood laminates creating large, strong panels.

Why it matters: CLT offers one of the most comprehensive sustainability benefits of any structural material. Using CLT can lower a building's carbon footprint by up to 26.5% compared to concrete or steel framing.

Construction advantages:

Large prefabricated panels reduce labor demands

Cuts down construction waste significantly

Dramatically speeds construction timelines

Sequesters carbon throughout building lifespan

Aesthetically appealing for modern architectural designs

Current adoption: CLT is rapidly gaining ground for environmentally conscious clients and represents a serious alternative to traditional framing methods.

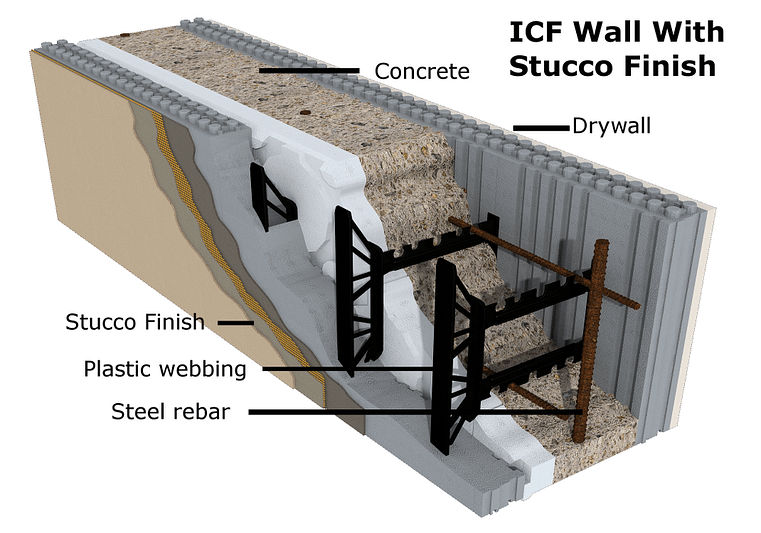

7. Insulated Concrete Forms (ICFs): Energy Efficiency in Every Block

What it is: Interlocking foam blocks that create insulated walls with concrete reinforced within, acting as both permanent formwork and insulation.

Why it matters: ICFs outperform traditional wood framing significantly in energy efficiency. These forms create walls with superior thermal performance, resulting in measurable savings in utility bills and improved durability against extreme weather.

Benefits:

Superior insulation compared to conventional framing

Interlocking design ensures consistent wall quality

Enhanced durability against extreme weather events

Reduced thermal bridging

Long-term homeowner savings through reduced HVAC costs

8. Ferrock: Carbon-Negative Concrete Alternative

What it is: An eco-friendly building material made from waste iron and other industrial byproducts that absorbs carbon dioxide during curing.

Why it matters: Ferrock is not just sustainable, it's carbon-negative. The material actively absorbs CO₂ from the atmosphere during its curing process, making it a climate-positive building material.

Performance characteristics:

More flexible and durable than traditional concrete

Highly resistant to corrosion, chemicals, and saltwater

Suitable for harsh marine environments

Represents a significant advancement in sustainable construction

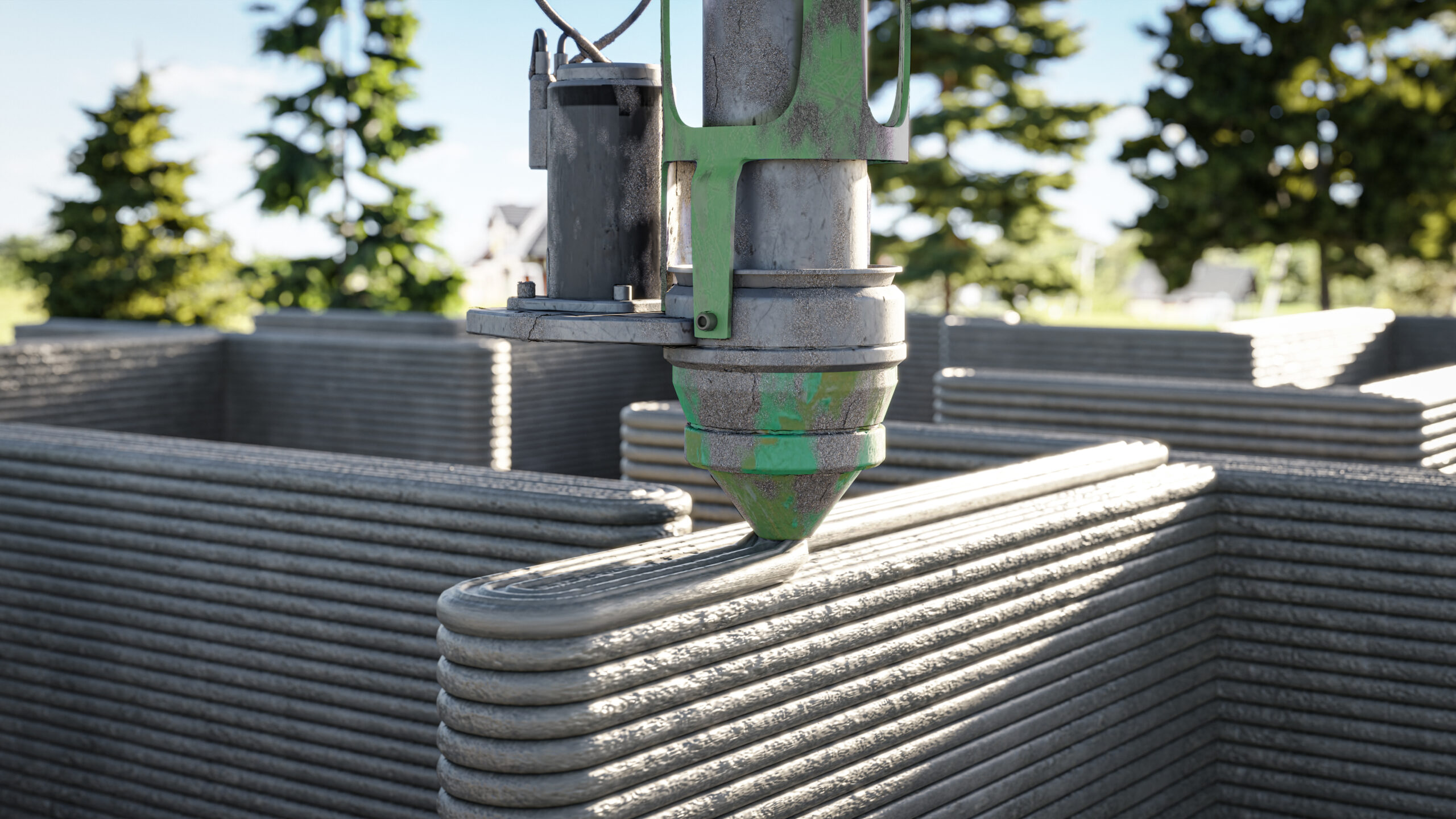

9. 3D-Printed Concrete Elements: Customization Meets Efficiency

What it is: Architectural elements and structural components created using 3D printing technology with concrete, clay, or polymer mixes.

Why it matters: 3D printing fundamentally changes construction economics. It reduces environmental waste, labor costs, and enables highly customized design solutions previously impossible with traditional methods.

Revolutionary benefits:

Robotic precision enables complex geometries

Minimal waste through precise material application

Dramatically shorter production timelines

Customized architectural elements without molds

Rapid affordable housing solutions

Modular housing units scalable for various applications

Scalability: 3D printing is moving from demonstration projects to actual housing starts, with volumetric construction capable of reducing build schedules by 20-50%.

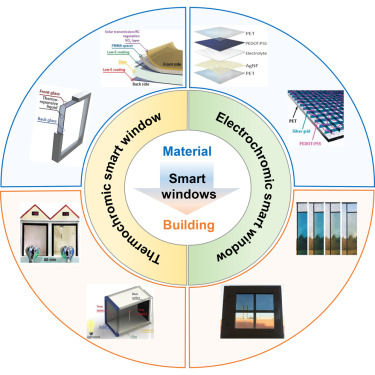

10. Smart Glass and Advanced Insulation Materials

What it is: Electrochromic glass that automatically adjusts transparency to regulate light and temperature, paired with advanced insulation foams and phase-change materials.

Why it matters: Smart glass is revolutionizing building envelope performance. It's no longer limited to high-end commercial buildings, smart glass is now being specified for residential projects and energy-conscious urban developments.

Performance data:

25-30% reduction in annual residential cooling loads (DOE 2024 data)

Automatic light and temperature regulation

Significantly reduced HVAC demands

Enhanced occupant comfort and productivity

Pairing advantage: When combined with advanced insulation foams and phase-change materials, buildings achieve entirely new performance levels.

11. Translucent Concrete: Light-Transmitting Innovation

What it is: Concrete based building material with embedded optical fibers (typically 4-5% by volume) that transmit light from natural or artificial sources.

Why it matters: Translucent concrete enables dramatic energy savings by allowing daylight into interior spaces, reducing electrical lighting demands. The unique aesthetic also opens entirely new architectural possibilities.

Design benefits:

Natural light penetration reduces daytime lighting energy usage

Creates distinctive visual effects with silhouettes visible through material

Suitable for façade materials and interior wall cladding

Enables energy-efficient green building designs

Uniform illumination throughout the day

Innovation heritage: Originally developed in 2001 by Hungarian architect Áron Losonczi, this technology continues to evolve and gain commercial viability.

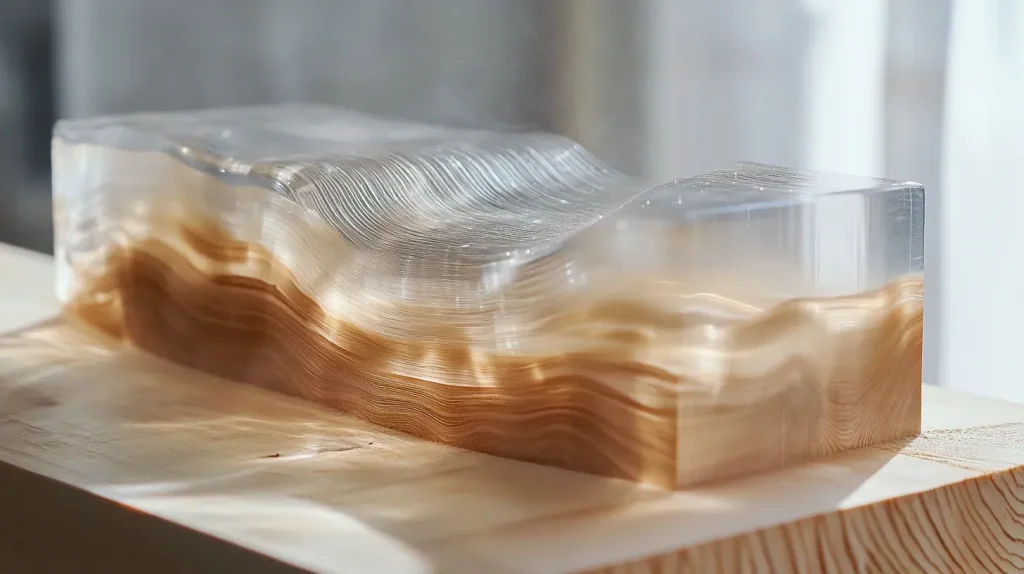

12. Transparent Wood: Nature's High-Tech Material

What it is: Composite material created by removing light-absorbing lignin from wood and impregnating the cellulose scaffold with transparent polymer, resulting in wood that's as transparent as glass.

Why it matters: Transparent wood combines sustainability with high-performance characteristics previously reserved for synthetic materials. It's stronger and more durable than conventional glass while maintaining wood's sustainability benefits.

Superior performance metrics:

90% optical transmittance (compared to conventional glass)

Fracture toughness of 3.2 MPa·m^0.5^ (vs. glass at 0.7-0.85)

Thermal insulation superior to conventional glass

Suitable for solar cell integration

Dramatically lower carbon footprint than traditional glass

Applications: Windows, skylights, solar cell substrates, and facades in energy-efficient buildings.

13. Aerogel Insulation: Extreme Thermal Performance

What it is: Super-insulating material with thermal conductivities as low as 13 mW/(m·K), approximately 2-2.5 times better than standard mineral insulation.

Why it matters: Aerogel achieves unmatched insulation performance in ultra-thin profiles. Where traditional insulation requires 8 inches of thickness, aerogel accomplishes equivalent insulation in just 2-3 inches.

Distinctive advantages:

Lowest thermal conductivity of any commercially available insulation

Ultra-thin installation reduces building profile

Maintains excellent light transmittance

Superior performance in confined spaces

Lightweight, preventing damage to delicate components

Hydrophobic properties provide moisture resistance

Application sweet spot: High-temperature applications, retrofit projects with limited space, and premium buildings where performance justifies higher material costs.

14. Phase-Change Materials (PCMs): Passive Temperature Control

What it is: Materials engineered to absorb heat at rising temperatures (changing from solid to liquid) and release heat at falling temperatures (returning to solid state), naturally regulating building temperature.

Why it matters: PCMs eliminate reliance on HVAC systems during temperature fluctuations, dramatically reducing energy consumption and building operational costs.

Mechanism of action:

Absorbs and stores thermal energy during temperature increases

Releases stored energy during temperature decreases

Passive operation without mechanical systems

Integrated into walls, floors, roofs, and ceilings

Performance impact: Buildings equipped with PCM composites experience significant reductions in heating and cooling loads, improving thermal comfort while cutting energy bills.

15. Photocatalytic Concrete: Air-Purifying Surfaces

What it is: Concrete infused with catalytic materials (typically titanium oxide) that decompose pollutants when exposed to light, natural or artificial.

Why it matters: Beyond construction, photocatalytic concrete actively improves air quality. It decomposes harmful gases from vehicle exhaust, VOCs, mold, bacteria, allergens, and odor-causing chemicals.

Environmental benefits:

Self-cleaning surfaces reduce need for harsh solvents

Decomposes atmospheric pollutants

Reduces urban heat island effect through cleaner reflective surfaces

Prevents smog formation by reducing chemical reactions from dirty surfaces

Maintains aesthetic appearance longer

Urban applications: Particularly valuable for congested cities where air quality is a concern.

16. Recycled Plastic Building Materials: Circular Economy in Action

What it is: Durable building materials created from post-consumer and post-industrial plastic waste, including recycled bricks, blocks, decking, fencing, and paving materials.

Why it matters: Recycled plastic materials address two critical problems simultaneously, plastic waste in landfills and the need for durable, water-resistant building components.

Real-world impact:

Diverts tons of plastic waste from landfills annually

Durable, water-resistant construction material

Cost-effective for low-income housing and affordable projects

Interlocking designs enable rapid assembly

Suitable for disaster relief shelters and rapid deployment housing

ByFusion converted 20 tons of ocean plastic waste into 4,000 construction-grade blocks

Versatility: Applications range from walls and cladding to landscaping and outdoor structures.

17. Cork Insulation: Renewable Natural Excellence

What it is: 100% natural, renewable insulation material harvested from cork oak tree bark without harming the trees.

Why it matters: Cork represents true renewable construction, cork oaks are harvested multiple times over their 200-year lifespans without being cut down.

Comprehensive sustainability:

100% renewable resource with regenerating bark

Supports biodiversity in cork oak forest ecosystems

Natural cellular structure provides excellent thermal insulation

Superior acoustic insulation properties

100% biodegradable at end-of-life

Fully recyclable and reusable

Performance characteristics: Provides excellent thermal performance while reducing heating and cooling loads, lowering carbon footprint and operational costs over building lifetime.

18. Permeable and Porous Concrete: Managing Water Strategically

What it is: Specialized concrete mixtures with controlled porosity that allow water to infiltrate rather than creating runoff, often combined with porous aggregate bases for stormwater management.

Why it matters: As extreme weather events intensify, stormwater management becomes critical infrastructure. Permeable pavements eliminate flooding risks while naturally filtering water and reducing pollution.

Environmental advantages:

Mitigates urban flooding

Improves stormwater management

Naturally filters water through aggregate layers

Drainage rates around 6.4 inches per hour

Void space of 8-25% depending on design

Reduces pollutant transport to groundwater

Applications: Parking lots, roadways, driveways, sidewalks, and any paved surfaces where water management is a concern.

Bonus Material: Carbon Concrete and Wood-Fiber Composites

Carbon Concrete

High-performance material combining concrete with carbon fibers, creating structures that are stronger, lighter, and more durable than traditional reinforced concrete. Carbon doesn't rust, eliminating the need for concrete covering, reducing sand consumption and CO₂ emissions by significant percentages.

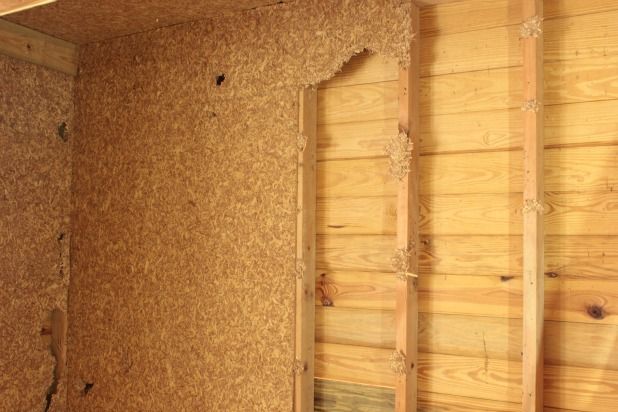

Wood-Sawdust Composites

Sustainable concrete alternatives created by replacing sand with processed wood sawdust. At optimal replacement ratios (10-20%), these materials improve thermal insulation, reduce concrete density, and represent an economically advantageous sustainable alternative to virgin aggregates.

The Future of Construction Is Here

These 18 innovative materials represent far more than incremental improvements in construction, they signal a fundamental shift in how the industry approaches building. From carbon-negative hempcrete to self-healing concrete, from graphene-enhanced superstructures to algae-based bio-blocks, the materials transforming construction align perfectly with global sustainability imperatives. The most successful construction companies in 2025 and beyond will be those that embrace these innovations. Early adoption positions your firm as a leader, appeals to environmentally conscious clients, meets evolving building codes, and often reduces long-term project costs.

At HKC Construction, we're committed to integrating these cutting-edge materials into our projects. Whether you're planning a residential development, commercial complex, or infrastructure project, we can help you evaluate which innovative materials best fit your specific needs, budget, and sustainability goals.

Ready to build the future? Contact HKC Construction today to discuss how these innovative materials can elevate your next project.